The reinforcement layer of alpine skis (Ski) is one of the key structural components that determines the performance, durability, stability, and elasticity of the skis. It is usually located between the top sheet and the core or on both sides of the core.Different brands and product categories use different materials and manufacturing techniques for their reinforcement layers.

Below are the most common types of reinforcement layers used in modern skis:

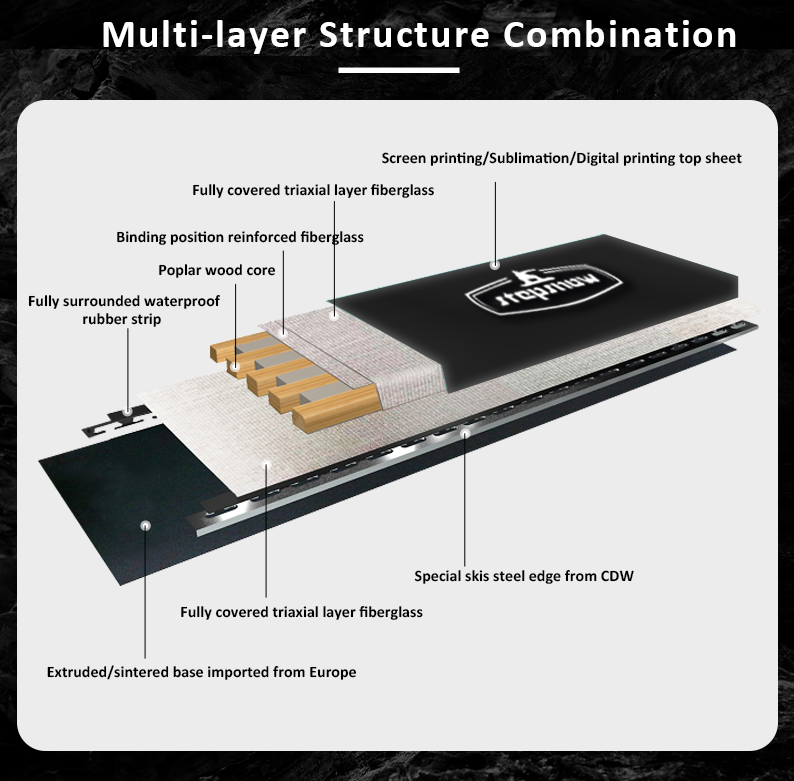

Fiberglass – Just about the most widely used composite in the ski industry. It’s cost-effective, easy to use, and provides energy and responsiveness when combined with a wood core. Raw fiberglass looks like a simple woven white fabric, but when combined with epoxy resin, which is then heated and pressed, it becomes extremely strong which aids in longitudinal and torsional stiffness, essentially strengthening the ski to reduce chatter. Downside…it’s heavy after being saturated in epoxy and degrades over time.

Carbon Fiber – Used in the same way as Fiberglass, but is much lighter and generates more energy or “pop”. These benefits come a much higher manufacturing cost which is why many brands are just using Carbon Stringers (strands of carbon fiber on top of the wood core) instead of full layers of Carbon Fiber that run over the entire core. Although it’s rad to say you have carbon fiber in your skis, it can be a tricky material to use effectively. Carbon is much less damp than fiberglass, so if a ski has too much carbon, or if it’s not balanced out effectively with a wood core with good damping properties, you’ll have much more vibration which makes your ski nervous or chattery. It’s a balancing act.

Titanal (Metal) – An aluminum alloy that is only manufactured by one company in the world; 95% of the time when a ski is referred to as having “metal” in it, we’re talking about Titanal. Plain and simple, Titanal adds power, stability and dampness to a ski. As you might have guessed from that description, it’s typically found in more aggressive all-mountain skis because of the added strength and grip on harder snow. Titanal can be used in full sheets above and below the core and run from tip to tail and edge to edge, or strips can be used in only in certain sections. While most skis that had layers of Titanal in the past used two full sheets, a lot of skis are moving in the direction of just strips of metal in certain sections as a way to reduce the overall weight of the ski. Typically, the Titanal sheets used are 0.5 – 0.8mm thick and can be cut into any shape which gives brands a plethora of options on where to put it and how much to use in their skis.

Aramid (Kevlar) – Most commonly known for being in bullet proof vests, this fiber is also sometimes used in skis and snowboards. The advantage of Aramid over carbon fiber is the damping and impact absorption properties, but again comes at a higher cost.

Prepreg – This is a term for a reinforced fabric like fiberglass or carbon fiber that has been “impregnated” with a resin (epoxy) and is ready to lay into the mold without having to add wet resin by hand. In order for the laminate to cure, and bond to the core, a combination of pressure and heat is used while in the press. There are several advantages to using Prepregs in ski manufacturing:

1.Consistency is probably the biggest advantage. You get the same ratio of resin every single time whereas brushing or rolling it on by hand typically creates an excess in some spots and dry spots in others. Perfect repeatability of every ski while applying resin by hand is essentially impossible.

2.Prepregs are much cleaner and produce much less waste. No mixing cups full of resin, no messy rollers, drips everywhere, plus you aren’t rushing to apply the resin before it sets up.

3.Not only do Prepregs have less curing time, but they also produce a smooth glossy surface that is virtually free of air bubbles.

FROM:March 27, 2025

How Skis Are Made: A Complete Guide to Ski Construction & Materials

What else do you know about reinforcement layers in skis?

You’re welcome to join the discussion!